47

Check Compressor Oil Level — After adjusting the

refrigerant charge, allow each circuit to run fully loaded for

20 minutes. Stop the compressors and check the oil level. Oil

level should be

1

/

8

to

3

/

8

up on the sight glass.

Add oil only if necessary to bring the oil into view in the

sight glass. If oil is added, run the circuit for an additional

10 minutes, then stop and check oil level. If the level remains

low, check the piping system for proper design for oil return;

also, check the system for leaks. If checking the oil level with

unit running in part load, let unit run one hour, then run at full

load for 10 minutes. If oil does not return to acceptable sight

glass levels, check for correct suction piping and line sizing.

Final Checks — Ensure all safety controls are operating,

control panel covers are on, and the service panels are in place.

Oil Charge

Puron systems use a polyol ester (POE) oil. Use only Carri-

er approved compressor oil. Oil should be visible in compres-

sor oil sight glass. An acceptable oil level is from

1

/

8

to

3

/

8

of

sight glass. All compressors must be off when checking oil lev-

el. Recommended oil level adjustment method is as follows:

ADD OIL — Recover charge from the outdoor section of the

unit and isolate the condensing unit using the liquid and suction

service valves. Add oil to suction line Schrader valve on tan-

dem compressors sets and the compressor Schrader on the trio

and single compressor circuits. (See Fig. 59 and 60.) When oil

can be seen at the bottom of the sight glass, add oil in 5 oz in-

crements which is approximately

1

/

8

in oil level. Run all com-

pressors for 20 minutes then shut off to check oil level. Repeat

procedure until acceptable oil level is present.

NOTE: Use only Carrier approved compressor oil. Approved

sources are:

Totaline . . . . . . . . . . . . . . . . . . . . . . .3MAF POE P903-1601

Mobil. . . . . . . . . . . . . . . . . . . . . . . . . . .EAL Arctic 32-3MA

Uniqema . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RL32-3MAF

Do not reuse oil that has been drained out, or oil that has

been exposed to atmosphere.

Actual Start-Up

NOTE: Refer to Start-Up Checklist on pages CL-1 to CL-5.

Actual start-up should be done only under supervision of a

qualified refrigeration mechanic.

VAV APPLICATIONS — C.TYP = 1 and 9

1. Start indoor fan motor.

2. Fan status switch input should close. Note the unit will

not start unless the Fan Status input is closed.

3. Unit C.TYP = 1: Using the scrolling marquee display,

set leaving set point (Set Point COOL CSP.1). Unit

C.TYP = 9: Using the 4 to 20mA input, set the control

point (Run Status VIEW CTPT) for leaving set

point.

4. Turn ENABLE/OFF/REMOTE CONTACT switch to

ENABLE position.

5. If supply air temperature is greater than the control point

the unit will start to stage up.

CV APPLICATION — C.TYP = 4

1. Start indoor fan motor.

IMPORTANT: Oil level should only be checked when the

compressors are off.

CAUTION

The compressor in a Puron

®

refigerant (R-410A) system

uses a polyol ester (POE) oil. This is extremely hygro-

scopic, meaning it absorbs water readily. POE oils can

absorb 15 times as much water as other oils designed for

HCFC and CFC refrigerants. Take all necessary precau-

tions to avoid exposure of the oil to the atmosphere. Failure

to do so could result in possible equipment damage.

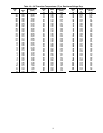

Fig. 60 — Typical Trio Compressor Assembly

LEGEND

DPT — Discharge Pressure Transducer

DTT — Discharge Temperature Thermistor

HPS — High Pressure Switch

RGT — Return Gas Temperature Sensor

SPT — Space Temperature Sensor

OIL SIGHT

GLASS

HPS B

DPT B

SUCTION

SCHRADER A

SUCTION

SCHRADER B

RGT A

HPS A

DPT A

DTT A

SPT A

RGT B SPT B

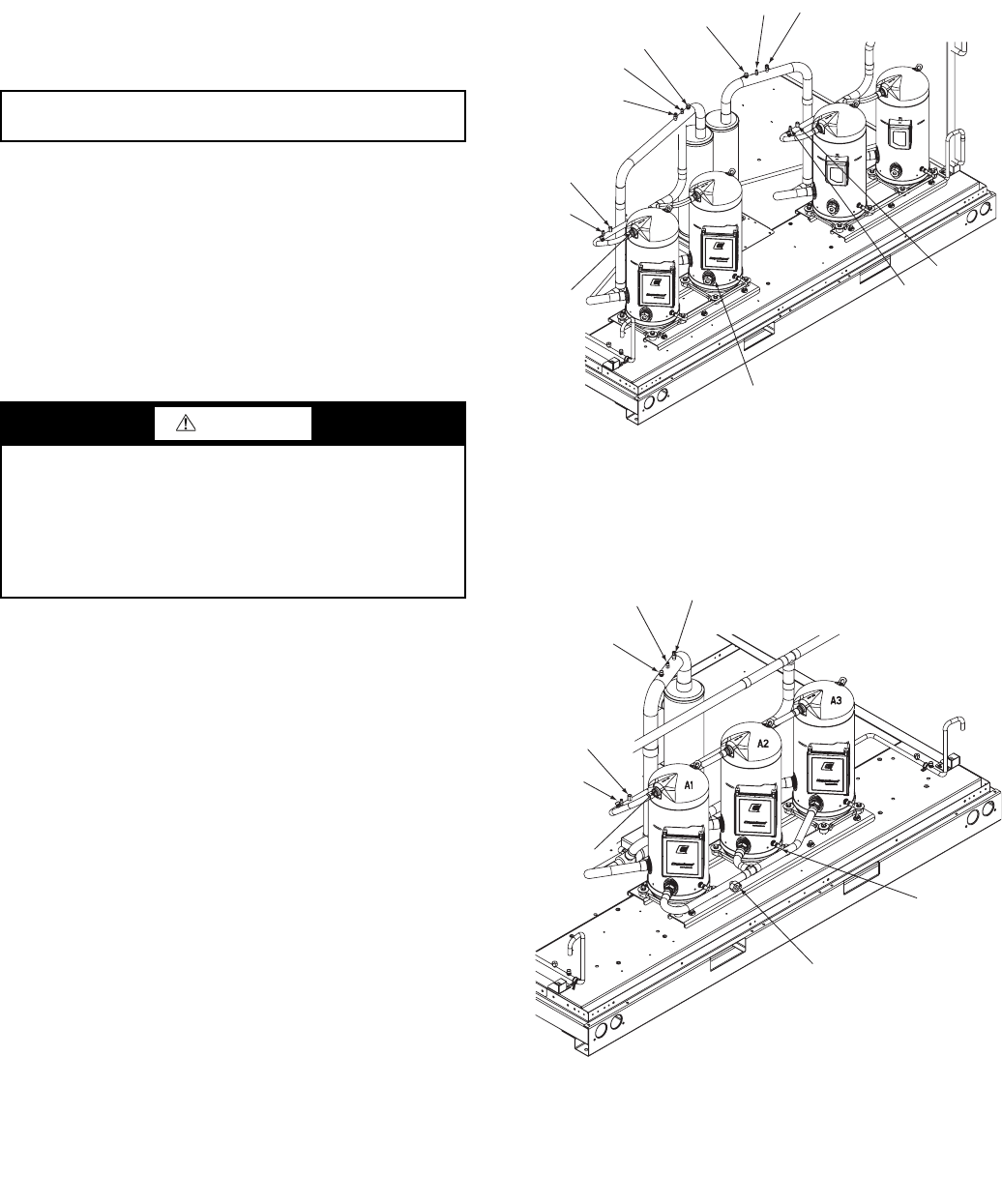

Fig. 59 — Typical Tandem Compressor Assembly

LEGEND

DPT — Discharge Pressure Transducer

DTT — Discharge Temperature Thermistor

HPS — High Pressure Switch

RGT — Return Gas Temperature Sensor

SPT — Space Temperature Sensor

SUCTION

SCHRADER A

OIL SIGHT

GLASS

RGT A

HPS A

DPT A

DTT A

SPT A

OIL ADD

LOCATION