TM

BRYAN STEAM

Form No. 6410

(5/00)

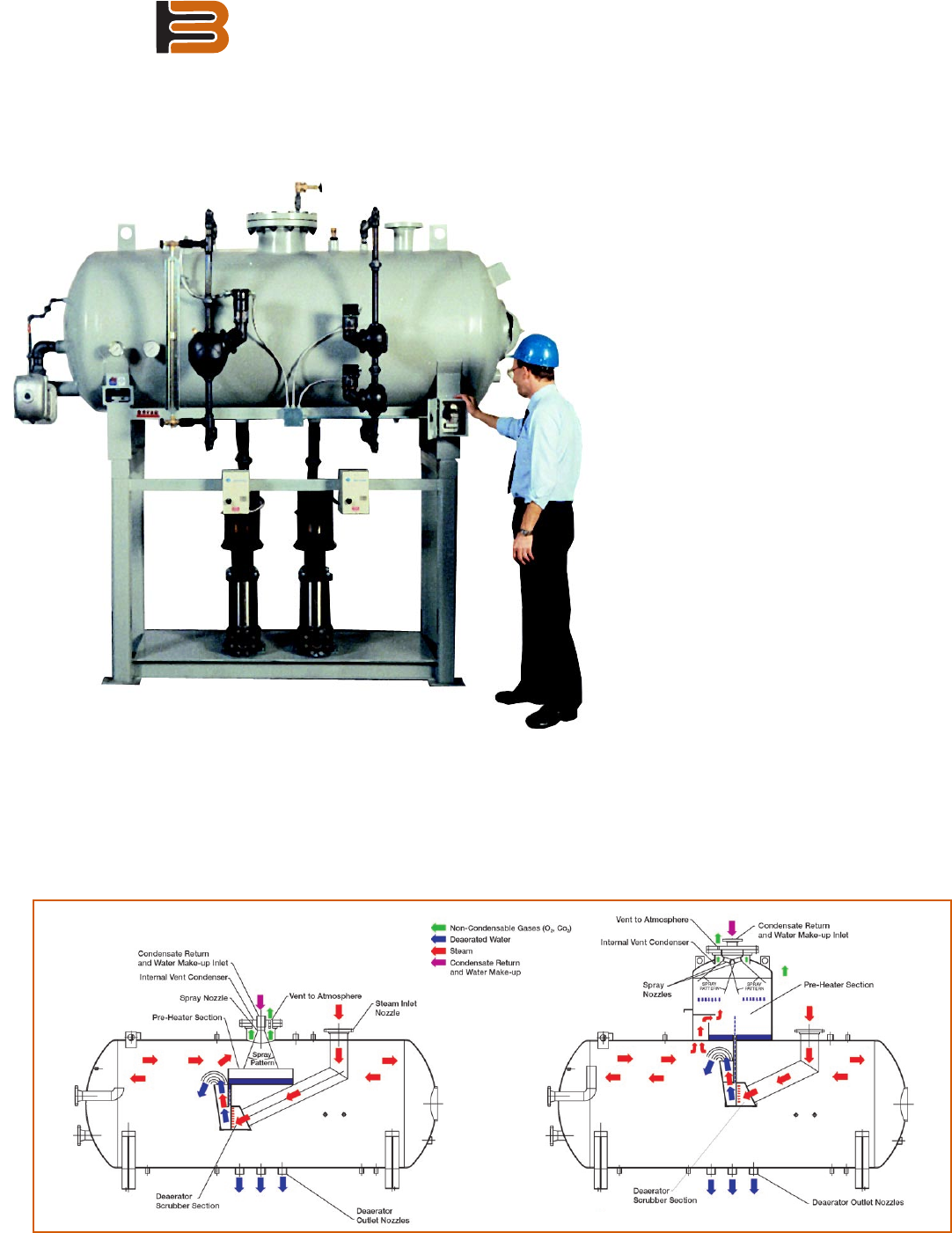

15,000 PPH unit shown

Spray Type Boiler Feedwater Deaerators

Capacities 5,000 to 60,000 PPH (145 to 1740 BHP)

Performance Features

• Oxygen removal to .005 cc/l (7 PPB)

•CO

2

removal to 0% measurable

• Reduce chemical costs

• Reduce boiler and system corrosion

• Improve boiler efficiency

• Pre-heat boiler feedwater

• Quick equipment payback,

compared to chemical oxygen removal

Construction Features

• Constructed to ASME Section VIII,

Division I for 50 PSIG

• Easily accessible manway

• Standard 10 minutes

deaerated water storage

• Internal vent condenser for minimum

steam loss

• Self-adjusting spring-loaded

stainless steel spray valve

• Structural steel stand/pump platform

• 2-stage deaeration

• Available as completely packaged unit

including pumps and control panel

The Bryan spray type deaerator is rated for oxygen

removal to .005cc/l (7 PPB) and CO

2

to zero measur-

able across its entire operating range. With its all

stainless steel spring loaded spray valve and second

stage steam scrubber, the spray type deaerator is a

good choice for all deaerator applications.

Units are available with a complete range of boiler

feedpumps and control options making them a total

deaerator package with minimal amount of field

assembly.

Integral

Tank Design

Horizontal

Tank Design