Applications manual | 11.2007Bosch Water Heating

Applications manual

| 9

2.6 Bosch GWH 345 ESR

Features:

Specifi cally designed for recirculating applications

Electronic ignition and built in power vent

GWH 345 ESR thermal effi ciency of 82%

Vents vertically or horizontally with 3" stainless steel (AL29-4C)

Direct vent room-sealed combustion

Computerized temperature control — ensures temperature

stability

Model GWH 345 ESR N for natural gas (NG) supply

Model GWH 345 ESR L for liquid propane (LP) supply

10-year warranty

GWH 345 ESR Technical Specifi cations

Gas input GWH 345 ESR: 32,000 - 95,000 Btu/h

Maximum fl ow rates GWH 345 ESR: 3.5gpm @ 45°F rise

Thermal Effi ciency 82%

Dimensions 27.5" h x 15.75" w x 11.75" d

Weight 47 lbs.

Modulating gas valve yes

Ignition Electronic

GWH 345 ESR Installation Specifi cations

Gas connection ¾" Male NPT

Water connections ¾" Male NPT

NG gas pressure Minimum: 5.5" W.C.

Maximum: 14" W.C.

LP gas pressure Minimum: 11" W.C.

Maximum: 14" W.C.

Electrical supply 120VAC - plugs in

Venting 3" stainless steel (AL29-4C)

direct vent

room-sealed combustion

GWH 450 ESR Installation Clearances

Top (A) 12"

Front (B) 1"

Back 0"

Sides 1"

Floor (C) 12"

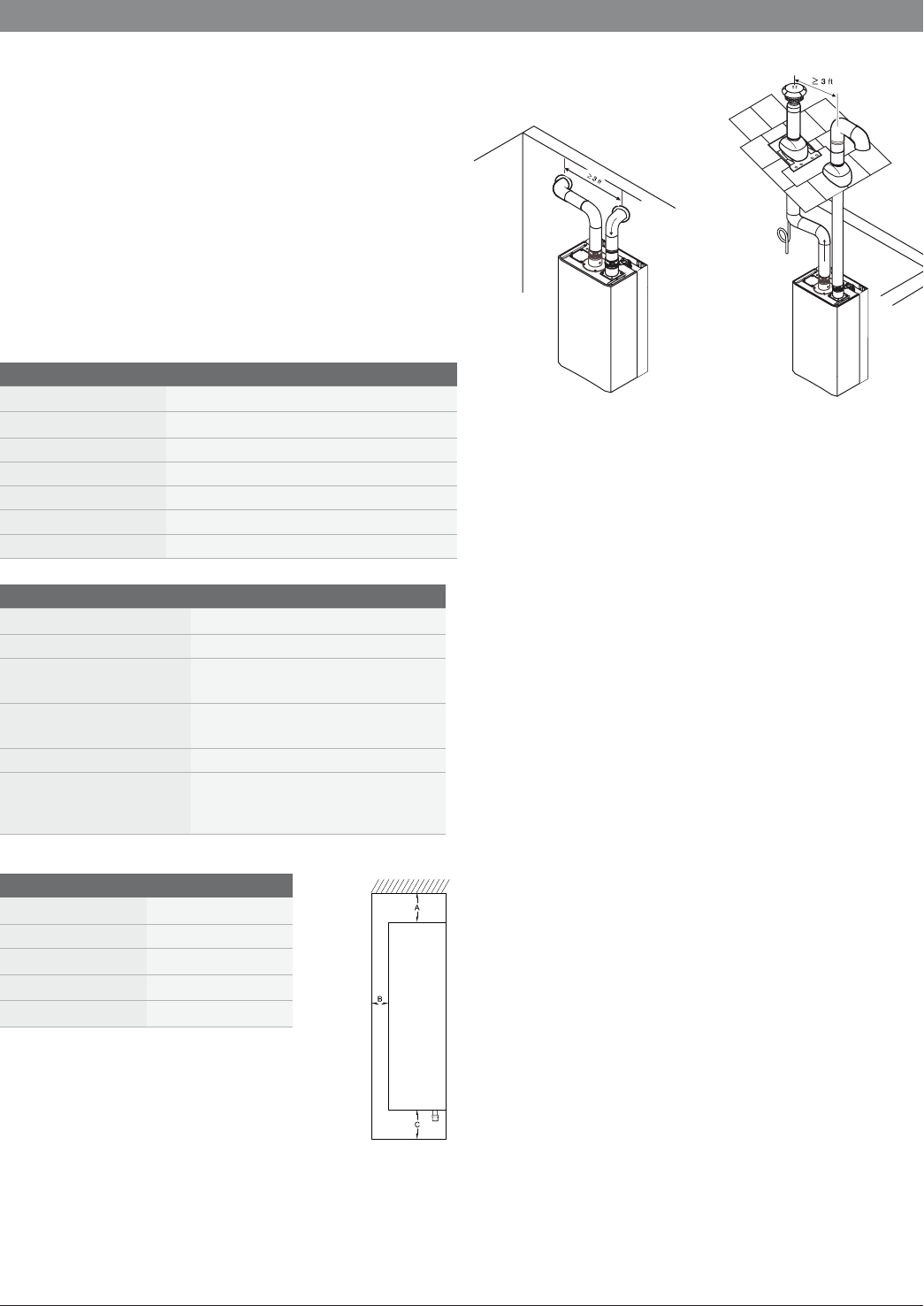

Fig. 1 Venting confi gurations

Installation guidelines:

Venting:

Must be 3" or 4" AL29-4C sealed stainless steel vent pipe.

Slope horizontal runs up to termination ¼" per foot. The horizon-

tal section between last elbow and termination must slope down

to the termination ¼" per foot.

Do not combination vent with any other appliance.

Always install an external condensate drain except when termi-

nating horizontally with less than 3 feet of pipe.

See manual for vent terminator clearances.

Gas piping:

Heater will not function properly without adequate supply gas

pressure.

Any appliance connector should be ¾" minimum diameter

Plumbing:

Install the included pressure relief valve and pipe to suitable

drain.

Minimum piping diameter is ¾".

Do not solder directly to the bottom of the unit.

Use unions to facilitate easy future maintenance.

Use full port ball valves for isolation valves.

Partially fi ll condensate drain tube loop with water prior to start

up.