The furnace may be installed with a one-pipe system

with gravity feed

or

lift. The maximum allowable lift

on a single line system is 8 feet. Lift should be

measured from the bottom (outlet)

of

the tank,

to

the

inlet

of

the burner. Sizing a single line system is

complex because

of

the difficulty estimating the

pressure drop through each fitting, bend and

component in the line. In general, keep single line

systems short as possible. Two-stage oil pumps are

available for either the INTERburner or Beckett

burner.

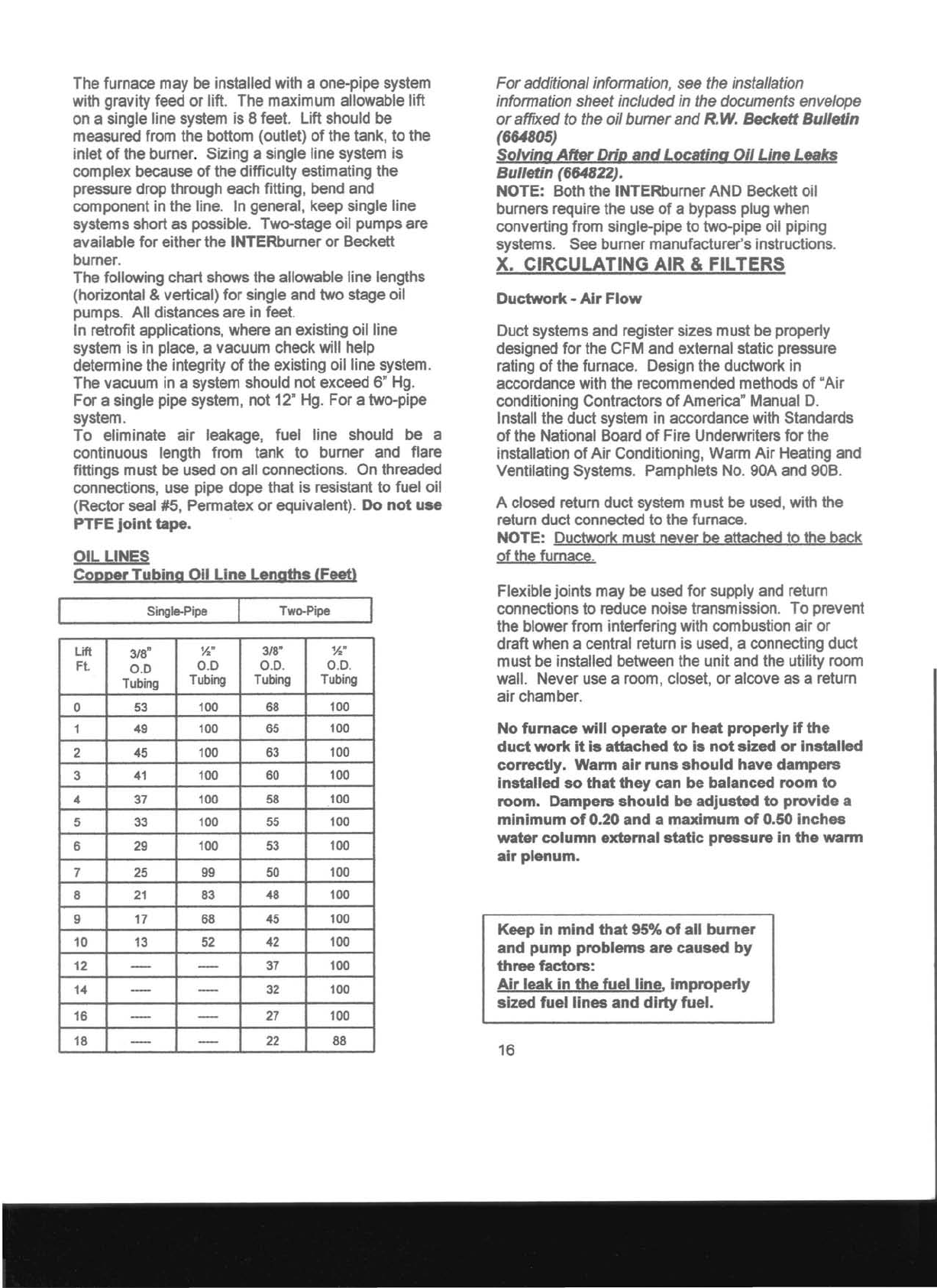

The following chart shows the allowable line lengths

(horizontal & vertical) for single and two stage oil

pumps. All distances are in feet.

In retrofit applications, where an existing oil line

system is in place, a vacuum check will help

determine the integrity

of

the eXisting oil line system.

The vacuum in a system should not exceed 6" Hg.

For a single pipe system, not 12" Hg. For a two-pipe

system.

To

eliminate air leakage, fuel line should be a

continuous length from tank to burner and flare

fittings must

be

used on all connections. On threaded

connections, use pipe dope that is resistant to fuel oil

(Rector seal #5, Permatex or eqUivalent). Do

not

use

PTFE

joint

tape.

OIL

LINES

Copper

Tubing

Oil

Line

Lengths

(Feet)

Single-Pipe

Two-Pipe

Lift

Ft.

3/8"

0.0

Tubing

Yo"

0.0

Tubing

3/8"

0.0.

Tubing

Yo"

0.0.

Tubing

0

53

100

68

100

1

49

100

65

100

2

45

100

63

100

3

41

100

60

100

4

37

100

58

100

5

33

100

55

100

6

29

100

53

100

7

25

99

50

100

8

21

83

48

100

9 17 68

45

100

10

13

52

42

100

12

- -

37

100

14

- -

32

100

16

- -

27

100

18

--

-

22

88

For additional information,

see

the

installation

information sheet included

in

the documents envelope

or affixed

to

the

oil burner and

R.

W.

Beckett

Bulletin

(664805)

SoMng

After

Drip

and

Locating

Oil

Line

Leaks

Bulletin (664822).

NOTE: Both the INTERburner AND Beckett oil

burners require the use

of

a bypass plug when

converting from single-pipe to two-pipe oil piping

systems. See burner manufacturer's instructions.

X.

CIRCULATING AIR & FILTERS

Ductwork·

Air

Flow

Duct systems and register sizes must be properly

designed for the CFM and external static pressure

rating

of

the furnace. Design the ductwork in

accordance with the recommended methods

of

"Air

conditioning Contractors

of

America" Manual

D.

Install the duct system in accordance with Standards

of

the National Board

of

Fire Underwriters

for

the

installation

of

Air

Conditioning, Warm

Air

Heating and

Ventilating Systems. Pamphlets

No.

90A and 90B.

A closed return duct system must be used, with the

return duct connected to the furnace.

NOTE: Ductwork must never

be

attached to the back

of

the furnace.

Flexible joints may be used for supply and return

connections to reduce noise transmission.

To

prevent

the blower from interfering with combustion air

or

draft when a central return is used, a connecting duct

must be installed between the unit and the utility room

wall. Never use a room, closet, or alcove as a return

air chamber.

No

furnace

will

operate

or

heat

properly

if

the

duct

work

it

is

attached

to

is

not

sized

or

installed

correctly.

Warm

air

runs

should

have

dampers

installed

so

that

they

can

be

balanced

room

to

room.

Dampers

should

be

adjusted

to

provide

a

minimum

of

0.20

and

a

maximum

of

0.50

inches

water

column

external

static

pressure

in

the

warm

air

plenum.

Keep

in

mind

that

95%

of

all

burner

and

pump

problems

are

caused

by

three

factors:

Air

leak

in

the

fuel

line,

Improperly

sized

fuel

lines

and

dirty

fuel.

16